Share

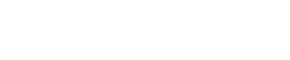

Composite cable tray (lined with steel plate)

Still hesitating? Get a sample first and contact us!

Categories:

- Product Description

-

Fireproof spray coating cable tray is a type of cable tray with fireproof function and surface treated with spray coating. The following is the relevant introduction:

Structure and Material

Structural forms

● There are various types of structures such as groove type, tray type, and ladder type. The trough type is a fully enclosed structure with a cover plate, which can effectively protect cables and is suitable for control cables in high-sensitivity systems; Tray type with or without holes, perforated trays have good protection, while perforated trays are lightweight and have high loads; The ladder structure is simple, with good heat dissipation and breathability, suitable for cables with larger diameters.

Material composition

● Substrate: Low carbon steel plates, aluminum plates, stainless steel plates, galvanized iron pieces and other metal sheets are usually used to provide basic strength and rigidity for the bridge.

● Fireproof materials: generally composed of fire-resistant boards composite of glass fiber reinforced materials and inorganic adhesives, or fire-resistant coatings added to the surface. Fireproof coating uses polymer synthetic resin as the film-forming material, combined with flame retardants, foaming agents, carbonization agents, and high-temperature refractory materials.

● Spray material: It is a thermosetting powder that adheres to the surface of the bridge through electrostatic spraying technology to form a uniform coating.

Characteristic

● Superior fire resistance: When exposed to fire, fireproof coatings or fireproof boards can play a role. Fireproof coating will continuously foam and expand at high temperatures, forming a flexible sponge like carbonized insulation layer that prevents heat transfer, prevents the steel structure carried by the bridge from softening and deforming, and delays the spread of fire.

● Good anti-corrosion performance: The spray coating on the surface can effectively block air, moisture, and corrosive substances from coming into contact with the metal substrate, preventing the bridge from rusting and being corroded. It is suitable for humid, corrosive gas or liquid environments.

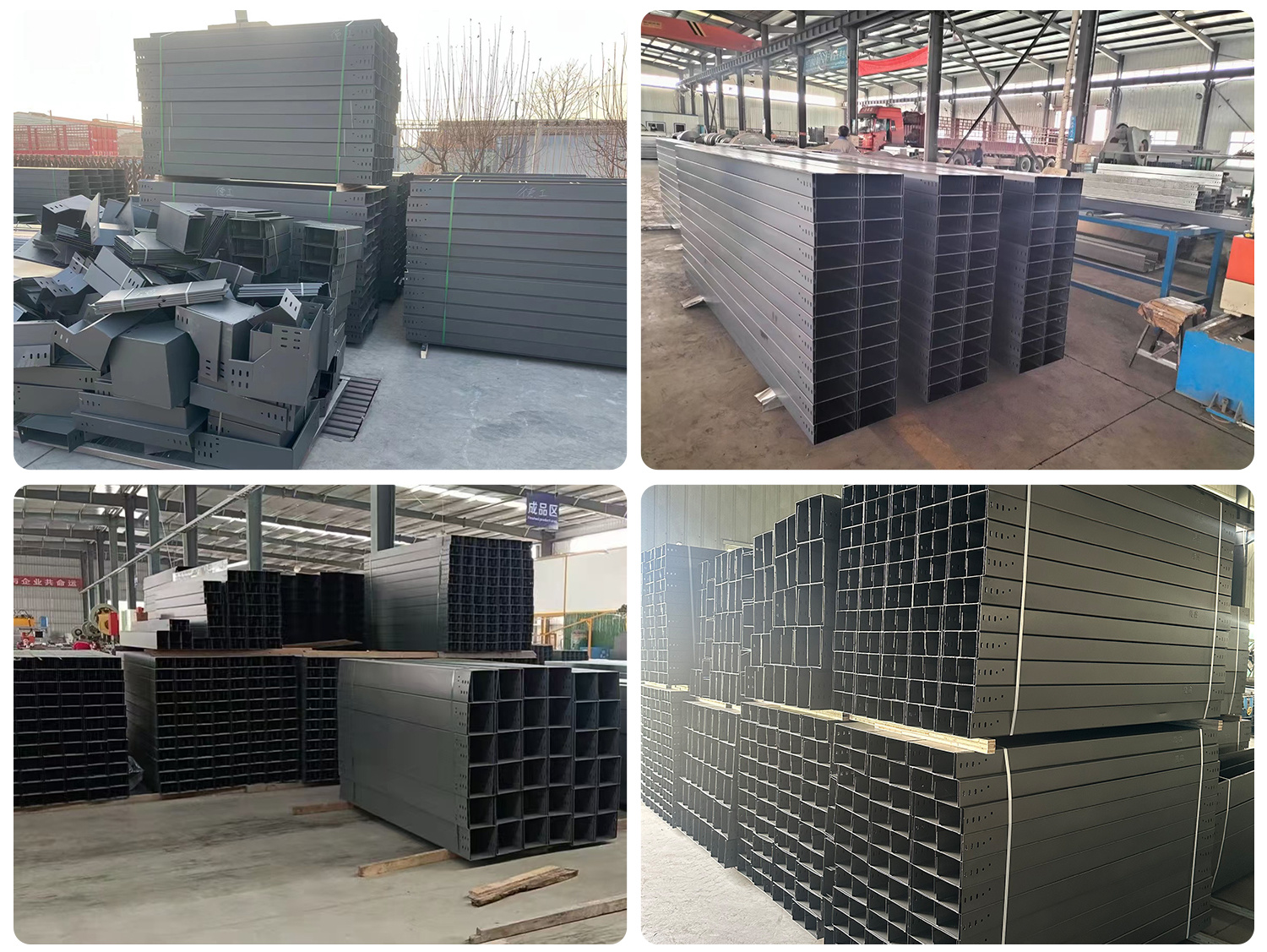

● Beautiful and diverse appearance: The spray coating process can make the surface of the bridge smooth and the color uniform. There are multiple colors to choose from, such as commonly used dark gray, and can also be customized according to the project environment to better integrate with the surrounding environment.

● High mechanical strength: Using metal as the substrate ensures that the bridge has high strength and rigidity, can withstand large loads, and can meet the needs of different cable laying.

● Easy installation and maintenance: adopting modular design, regular size, relatively light weight, and can be flexibly combined according to the on-site situation during installation. Smooth surface, less prone to dust and dirt, easy to clean, strong corrosion resistance, long service life, and low maintenance cost.

Application Area

● In the field of architecture, it is used to lay strong and weak electrical system cables such as lighting cables, network cables, telephone cables, etc. in densely populated places such as commercial buildings, office buildings, hospitals, schools, and residential buildings to ensure cable safety and prevent the spread of fire through cables in case of fire.

● In the industrial field, it can be used to lay power cables, control cables, and communication cables in factories such as petroleum, chemical, metallurgical, and power. It can protect cables in harsh industrial environments while meeting fire prevention requirements.

● In the field of transportation, it is used to lay signal cables, power cables, etc. in stations, tunnels, and other places of rail transit projects such as subways, light rails, and railways, as well as in tunnels and monitoring centers of highways, to ensure the safety of signal transmission and power supply in the transportation system.

● In the field of public facilities, it is used for cable laying in large public facilities such as airports, train stations, sports venues, and exhibition halls. It not only meets the functional requirements of cable laying, but also enhances the overall aesthetics of the building. It can also ensure the safety of personnel and equipment in the event of a fire.

Key points of installation

● Installation preparation: Before installation, check whether the specifications, models, and quantities of the bridge and accessories meet the requirements, whether the appearance is damaged or deformed, and prepare installation tools and materials.

● Installation of supports and hangers: Determine the position and spacing of supports and hangers according to the design, install them firmly, ensure levelness and verticality, and ensure smooth installation of cable trays.

● Bridge connection: Special connectors such as connecting plates and bolts should be used to connect the bridges. The connection should be tight, the interface should be flat and aligned, the bolts should be tightened, and anti loosening measures should be taken if necessary.

● Grounding treatment: The fireproof spray painted cable tray needs to be reliably grounded. The tray can be connected to the grounding system through grounding bolts or grounding flat steel to ensure that the grounding resistance meets the requirements.

● Fire prevention treatment: In sections with fire prevention requirements, fire-resistant or flame-retardant board and mesh materials should be added to the bridge frame according to regulations to form a closed or semi closed structure, and ensure that the fireproof materials are installed firmly.

Maintenance

● Regular inspection: Regularly check the appearance of the bridge for deformation, corrosion, and damage, whether the spray coating has fallen off, whether the connectors are loose, whether the supports and hangers are firm, and whether the fireproof materials are damaged or ineffective. If any problems are found, repair or replace them in a timely manner.

● Cleaning work: Regularly clean the dust, dirt, and debris on the surface of the bridge to prevent corrosive substances from adhering and affecting the performance and service life of the bridge.

● Fire performance inspection: Regularly check the fire performance of fireproof coatings or fireproof boards. If the fire performance is found to have decreased or does not meet the requirements, timely treatment or replacement should be carried out.

Composite cable tray (lined with steel plate)

Still hesitating? Get a sample first and contact us!

Categories:

Product Inquiry

Note: We will contact you within one working day, please pay attention to your email.