Share

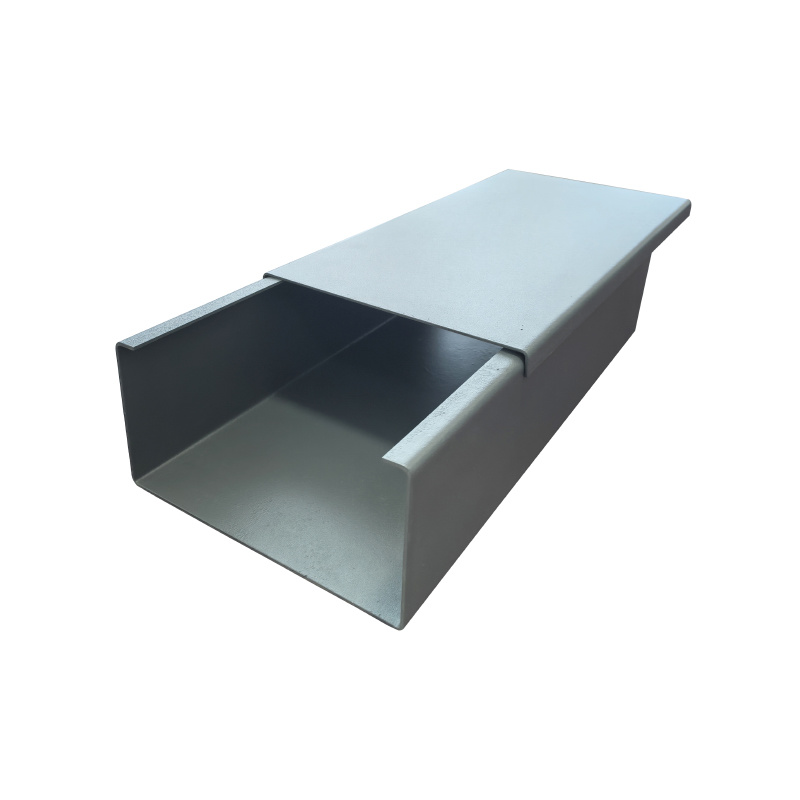

Aluminum alloy trough cable tray

Still hesitating? Get a sample first and contact us!

Categories:

- Product Description

-

Aluminum alloy cable tray is a device made of aluminum alloy as raw material for laying and protecting cables. The following is a detailed introduction:

Structure and Material

● Structural forms: There are various structures such as groove type, tray type, ladder type, and cable rack. The trough type is a fully enclosed structure with a cover plate, which can effectively protect the cable; Tray type with or without holes, perforated trays have good protection, while perforated trays are lightweight, have high load capacity, and good breathability; The ladder structure is similar to a ladder, with a horizontal bar in the middle for reinforcement, making it convenient for cable laying and fixing; Cable trays are usually used for wiring in computer rooms and can be flexibly combined.

● Material composition: The main components include copper, silicon, magnesium, zinc, manganese, etc., and the secondary alloying elements include nickel, iron, titanium, chromium, lithium, etc. The surface is often subjected to anodizing treatment to form an oxidation protective film.

Characteristic

● Lightweight: The density of aluminum alloy is only about one-third of that of steel, making it easy to handle, install, and maintain, and reducing the burden of structural support.

● Strong corrosion resistance: The naturally generated oxide layer and anodized surface of aluminum alloy can effectively resist the corrosion of chemicals such as atmosphere, moisture, acid and alkali, and are suitable for humid and corrosive environments.

● High strength and rigidity: With high strength and rigidity, it can support large cable loads and ensure the safe operation of cables.

● Anti electromagnetic interference: After surface anodizing, the anti electromagnetic interference, especially the anti shielding interference performance, is excellent, which is an irreplaceable advantage of steel bridge frames.

● High aesthetic appeal: Usually using anodizing technology, the finished product has a bright surface color and is not easily faded, which can improve the aesthetic appeal of the surrounding environment.

● Good conductivity: Helps with the grounding and electrical safety of the bridge system.

Application Area

● In the industrial field, it is widely used in chemical plants, power plants, oil platforms, etc., and can provide reliable support for cables in highly corrosive and demanding environments.

● In the field of architecture, it is suitable for commercial and public buildings such as office buildings, shopping malls, hospitals, schools, as well as residential buildings. It not only meets the needs of cable laying, but also enhances the aesthetics of the building.

● Outdoor engineering: such as tunnels, bridges, outdoor substations and other outdoor cable wiring projects, with their weather resistance, can be stably used in various outdoor environments.

● In the field of communication, aluminum alloy cable trays are widely used for wiring in communication rooms such as China Mobile, China Unicom, and China Telecom, making the wiring more standardized and regulated.

Key points of installation

● Stable connection: Usually connected through bolts, nuts, or specialized connectors. During installation, ensure that the connection is tight and the interface is flat and aligned.

● Reasonable fixation: Select appropriate supports and hangers based on the type of bridge and load-bearing requirements, and ensure that the supports and hangers are installed firmly and spaced reasonably.

● Pay attention to the environment: In corrosive environments, additional protective measures should be taken; In places with fire prevention requirements, fire prevention measures can be taken as needed.

● Grounding treatment: To ensure electrical safety, the bridge should be reliably grounded, which can be connected to the grounding system through grounding bolts or grounding flat steel.

Maintenance

● Regular inspection: Check the appearance of the bridge for deformation, scratches, wear, damage to the oxide layer, looseness of connectors, and firmness of supports and hangers. If any problems are found, repair or replace them in a timely manner.

● Cleaning work: Regularly clean the surface of dust, dirt, and debris to avoid the adhesion of corrosive substances.

● Damage repair: For minor scratches and wear on the surface, repair treatment can be carried out; Damaged parts should be replaced promptly.

Aluminum alloy trough cable tray

Still hesitating? Get a sample first and contact us!

Categories:

Product Inquiry

Note: We will contact you within one working day, please pay attention to your email.