Share

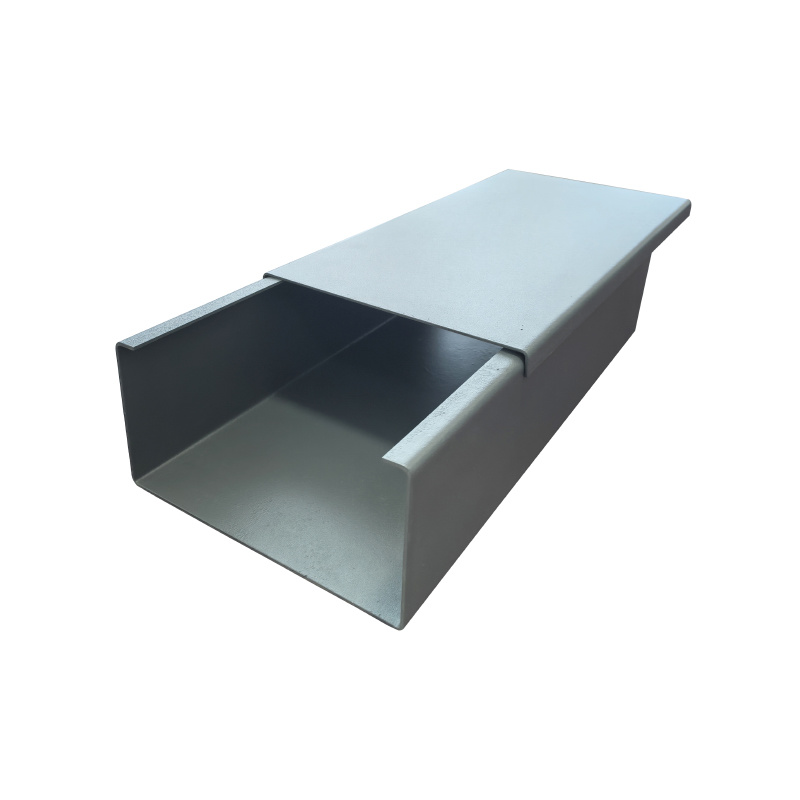

Stainless steel cable tray

Still hesitating? Get a sample first and contact us!

Categories:

Label:

- Product Description

-

Stainless steel cable tray is a device made of stainless steel as the main material for supporting and protecting cables. The following is a specific introduction:

Structure and Material

● Structural forms: including groove type, tray type, ladder type, and mesh format. The trough type is a fully enclosed structure with a cover plate, which can effectively protect cables and is suitable for places with high requirements for cable shielding; Tray type with or without holes, perforated trays have good protection, while perforated trays are lightweight, have high load capacity, and good breathability; The ladder structure is similar to a ladder, which facilitates cable laying and heat dissipation; The grid format cable tray has an open structure for easy observation and maintenance of cables.

● Material composition: Commonly used stainless steel materials include 304, 316, 316L, etc. The main alloying elements include chromium (Cr), nickel (Ni), molybdenum (Mo), etc. Chromium makes stainless steel corrosion-resistant, nickel can improve the toughness and corrosion resistance of stainless steel, and molybdenum can enhance corrosion resistance, especially in environments containing chloride ions.

Characteristic

● Strong corrosion resistance: It has high resistance to the erosion of most acids, alkalis, and salts, and can effectively resist the corrosion of chemical vapors, salt spray, etc. It has obvious advantages in environments such as chemical plants and coastal areas.

● Good high temperature resistance: It can maintain good mechanical properties and stable physical structure in high temperature environments, withstand temperatures of 400 ° C and below, and is suitable for high-temperature operation areas such as thermal power plants and metallurgical plants.

● High mechanical strength: It has high strength and rigidity, can withstand large cable loads, has good anti vibration performance, and can ensure the safe operation of cables.

● Anti electromagnetic interference: It has certain anti electromagnetic interference performance and can provide a good electromagnetic shielding environment for sensitive cables, ensuring the stability of signal transmission.

● Beautiful and durable: The surface is smooth, the color is beautiful, and it is not easy to rust or discolor. It has a long service life and does not require frequent maintenance and replacement.

● Environmental hygiene: Stainless steel material is non-toxic and harmless, and will not cause harm to the environment and human health, meeting environmental protection requirements.

Application Area

● In the industrial field, it is used to lay power cables, control cables, and communication cables in factories such as petroleum, chemical, power, and metallurgy. It can be used stably for a long time in harsh industrial environments.

● In the field of architecture, it is suitable for the laying of strong and weak electrical system cables in commercial buildings, office buildings, residential and other building projects, such as lighting cables, network cables, etc. It can meet functional requirements and enhance the aesthetics of buildings.

● In the field of transportation, it is used to lay signal cables, power cables, etc. in subway, light rail, railway and other rail transit projects, as well as in tunnels, monitoring centers and other places on highways, to ensure the normal operation of transportation facilities.

● Data center: It can provide reliable support and protection for a large number of cables in the data center, meet the high requirements of cable management in the data center, and ensure the safety and stability of data transmission.

Key points of installation

● Preparation before installation: Check whether the specifications, models, and quantities of the bridge meet the design requirements, and inspect the surface of the bridge for defects such as scratches and deformations.

● Connection and fixation: Usually bolted or welded, the connection should be firm, the interface should be flat, the bolts should be tightened and anti loosening measures should be taken.

● Grounding treatment: To ensure electrical safety, the bridge should be reliably grounded, which can be connected to the grounding system through grounding bolts or grounding flat steel. The grounding resistance should meet the requirements of relevant standards.

● Distance from other facilities: The bridge should maintain a certain distance from the walls, columns, etc. of the building for easy installation and maintenance.

Maintenance

● Regular inspection: Regularly inspect the appearance of the bridge frame for corrosion, deformation, damage, etc., check whether the connectors are loose, and whether the supports and hangers are firm.

● Cleaning work: Regularly clean the dust, dirt, and debris on the surface of the bridge to maintain its cleanliness.

● Anti corrosion treatment: For areas with slight corrosion, rust removal and anti-corrosion treatment can be carried out, such as applying anti-corrosion paint; Damaged parts should be replaced promptly in areas with severe corrosion.

Stainless steel cable tray

Still hesitating? Get a sample first and contact us!

Categories:

Label:

Product Inquiry

Note: We will contact you within one working day, please pay attention to your email.