Share

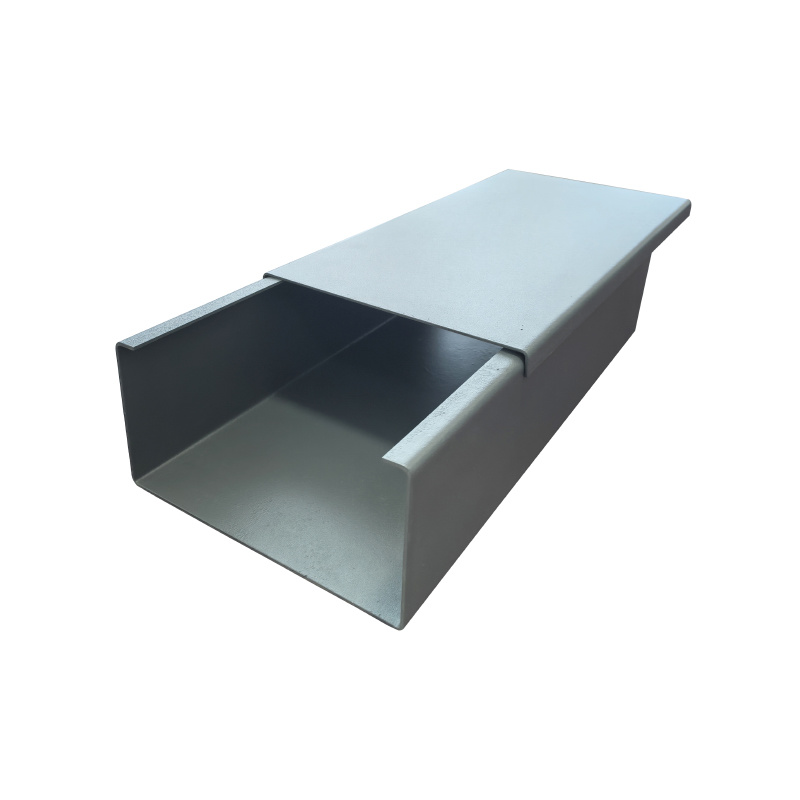

Hot dip galvanized cable tray

Still hesitating? Get a sample first and contact us!

Categories:

- Product Description

-

Hot dip galvanized cable tray is a cable tray made of cold-rolled steel plate and other metal materials, with the surface treated by hot-dip galvanizing process. The following is a specific introduction:

Structure and Material

● Structural forms: including groove type, tray type, and ladder type. The trough type is a fully enclosed structure with a cover plate, which can effectively protect the cable; Tray type is divided into perforated and unperforated types. Perforated trays are lightweight and have a high load capacity, while unperforated trays have good protection; The ladder structure is simple, with good heat dissipation and breathability.

● Material composition: Based on cold-rolled steel plates, hot-rolled steel plates, or galvanized steel plates, providing strength and rigidity. The surface is formed with a zinc layer through hot-dip galvanizing process, and the thickness of the zinc layer shall not be less than 65 μ m for thin plates below 5mm and not less than 86 μ m for thick plates, including a zinc iron alloy layer.

Characteristic

● Excellent anti-corrosion performance: In the liquid state of zinc, the steel surface is not only coated with a thick layer of pure zinc, but also forms a zinc iron alloy layer, which can effectively resist the erosion of chemical substances such as moisture and acidity in the air, and is suitable for corrosive environments such as humidity and chemical industry.

● Strong durability: The zinc layer has strong adhesion and is not easy to peel off. It can maintain good protective effect even in harsh outdoor environments, and its service life can usually reach 20 years or even longer.

● Good mechanical strength: Using metal as the substrate, the cable tray ensures high strength and rigidity, can withstand large loads, meet the needs of different cable laying, and provide stable support in heavy load or large-span installation.

● Good process characteristics: Due to the excellent ductility of zinc, its alloy layer adheres firmly to the steel base. After hot-dip galvanizing, the bridge can be formed into various shapes such as cold stamping, rolling, drawing, bending, etc. without damaging the coating. After hot-dip galvanizing of steel structural components, it is equivalent to one annealing treatment, which can effectively improve the mechanical properties of the steel substrate and eliminate the stress during the forming and welding of steel components.

● Good economy: Compared with stainless steel cable trays, hot-dip galvanized cable trays have lower costs and higher cost-effectiveness, making them a common choice for economical corrosion-resistant cable trays.

Application Area

● In the industrial field, it can be used to lay power cables, control cables, and communication cables in factories such as petroleum, chemical, and metallurgical industries, and can be used for a long time in harsh industrial environments.

● In the field of architecture, it is suitable for laying cables for strong and weak electrical systems in commercial buildings, office buildings, residential projects, etc., such as lighting cables, network cables, etc.

● In the field of electricity, it can be used for laying cables of different voltage levels in power plants, substations, distribution rooms and other electrical facilities, meeting the requirements for supporting and protecting power cables.

● Transportation field: Used for laying signal cables, power cables, etc. in subway, light rail, railway and other rail transit projects, as well as in tunnels, monitoring centers and other places on highways.

Hot dip galvanized cable tray

Still hesitating? Get a sample first and contact us!

Categories:

Product Inquiry

Note: We will contact you within one working day, please pay attention to your email.